Integrated Mirror Assembly & Machining Production Center

Our Integrated Mirror Assembly & Machining Center brings together large-scale assembly, precision metal processing, and advanced surface finishing to support high-volume manufacturing of bathroom mirrors, makeup mirrors, Hollywood mirrors, and customized LED mirror products.

The Large Mirror Assembly Workshop operates four efficient production lines with standardized SOPs, precision fixtures, and full functional testing for lighting, touch control, dimming, and anti-fog performance—ensuring consistent quality and stable lead times.

The Precision Metal & Machining Workshop provides complete in-house processing for aluminum frames, brackets, and structural parts, covering cutting, CNC drilling and milling, bending, welding, and laser fabrication. This allows high-accuracy component production and rapid turnaround for customized designs.

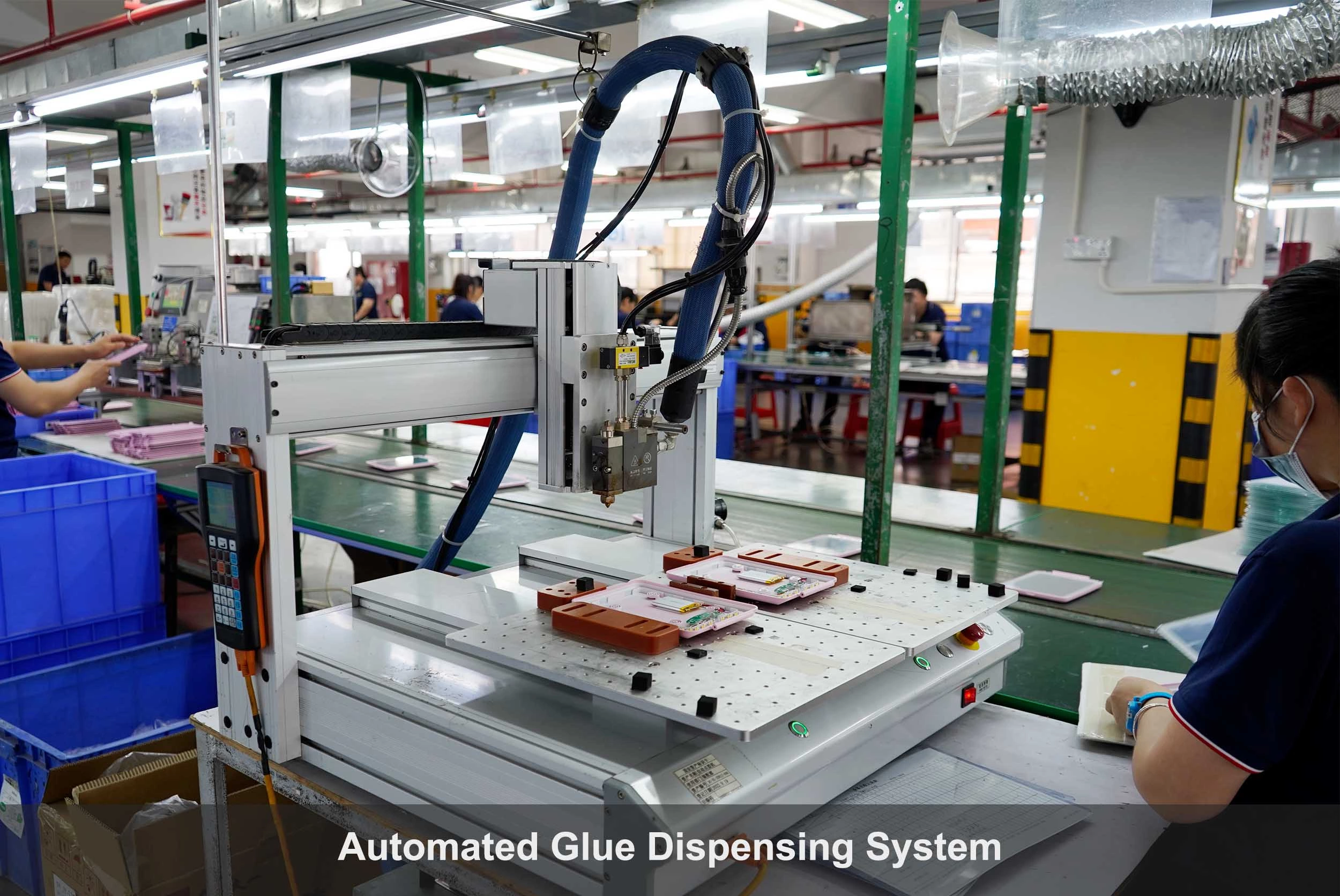

For small-format and portable mirrors, our Makeup Mirror Assembly Workshop runs 11 high-efficiency lines equipped with automated glue dispensing, ESD-safe stations, and in-line inspections including functional tests and burn-in aging to guarantee product reliability across all batches.

Additionally, the Silk-Screen & Decoration Workshop supports brand customization with in-house silk printing, pad printing, hot stamping, and water-transfer graphics, ensuring sharp, durable logos and decorative finishes with Pantone®-matched color accuracy.

Together, these integrated workshops enable streamlined production, flexible customization, and strict quality control—delivering stable, high-precision mirror products for global brands and large-scale OEM/ODM projects.

Contact UsHigh-Efficiency Makeup Mirror Assembly Lines

Our Makeup Mirror Assembly Workshop operates multiple high-efficiency production lines designed for stable, large-volume manufacturing. With standardized SOPs, balanced workflows, and well-trained operators, each assembly stage—from component preparation to final inspection—is executed with precision. This ensures consistent quality and reliable lead times for all makeup mirror and portable LED mirror products.

Large-Format Mirror Assembly Lines

Our Large Mirror Production Workshop operates multiple assembly lines dedicated to bathroom mirrors, full-length mirrors, and Hollywood-style vanity mirrors. Each line follows standardized assembly procedures, precision fixture setups, and multiple in-line inspections to ensure structural stability, uniform brightness, accurate touch control function, and long-term reliability. With experienced technicians and balanced workflows, the workshop supports continuous, high-volume output while maintaining consistent quality across a wide range of mirror sizes and configurations.