Mirror Glass CNC Fabrication Workshop

Our Large Glass CNC Fabrication Workshop is a fully automated production center designed to deliver high-precision glass components for premium mirror manufacturing. The workshop operates a complete in-house processing line that includes glass cutting, CNC edging, precision drilling, laminating, laser engraving, safety-film application, washing, and drying, ensuring every step is handled with accuracy and strict process control.

Equipped with advanced machinery such as CNC glass cutting machines, automatic loading systems, CNC edging and polishing machines, automatic drilling units, laser engraving machines, film laminators, and high-efficiency washing & drying systems, the workshop integrates automated workflow management to maintain consistent precision and reduce manual handling. Each piece of glass moves through a seamless CNC-driven sequence that enhances efficiency, minimizes defects, and supports stable large-scale production.

Throughout the entire process, strict quality inspections are implemented to verify dimensional accuracy, edge smoothness, hole precision, and surface cleanliness. Special attention is given to laminated and anti-shatter treatments, ensuring strong adhesion and safety performance that meets international standards. These rigorous quality controls allow us to produce glass components that meet the demanding requirements of LED bathroom mirrors, vanity mirrors, makeup mirrors, smart mirrors, and architectural-grade applications.

With flexible CNC capabilities, the workshop supports a wide range of shapes—round, oval, arched, rectangular, and irregular designs—along with technical cut-outs for switches, sensors, LED modules, and heating systems. This versatility enables us to respond efficiently to standard orders, OEM/ODM customization, and complex project specifications.

By combining modern automation, precision engineering, and a comprehensive production flow, the Large Glass CNC Fabrication Workshop plays an essential role in strengthening our overall manufacturing capacity. It ensures that every mirror product we deliver—whether for commercial, residential, or project-based applications—achieves excellent craftsmanship, reliable performance, and long-term durability.

Contact Us

Glass Cutting Machine

Our CNC Automatic Glass Cutting Machine ensures high-accuracy cutting for both standard and custom mirror designs. With digitally controlled motion paths and stable cutting pressure, each glass sheet is processed with precise dimensions and clean cutting lines. This level of accuracy provides the foundation for high-quality LED mirrors, bathroom mirrors, and specialized architectural glass components.

CNC Automatic Edging Machine

Our CNC Glass Edge Polishing Machine delivers perfectly smooth and uniform edges for mirrors and glass panels. Through automated contour tracking and high-precision grinding heads, the system ensures every piece achieves a refined, safe, and flawless finish. This level of polishing is essential for premium LED bathroom mirrors, framed designs, and custom geometric shapes.

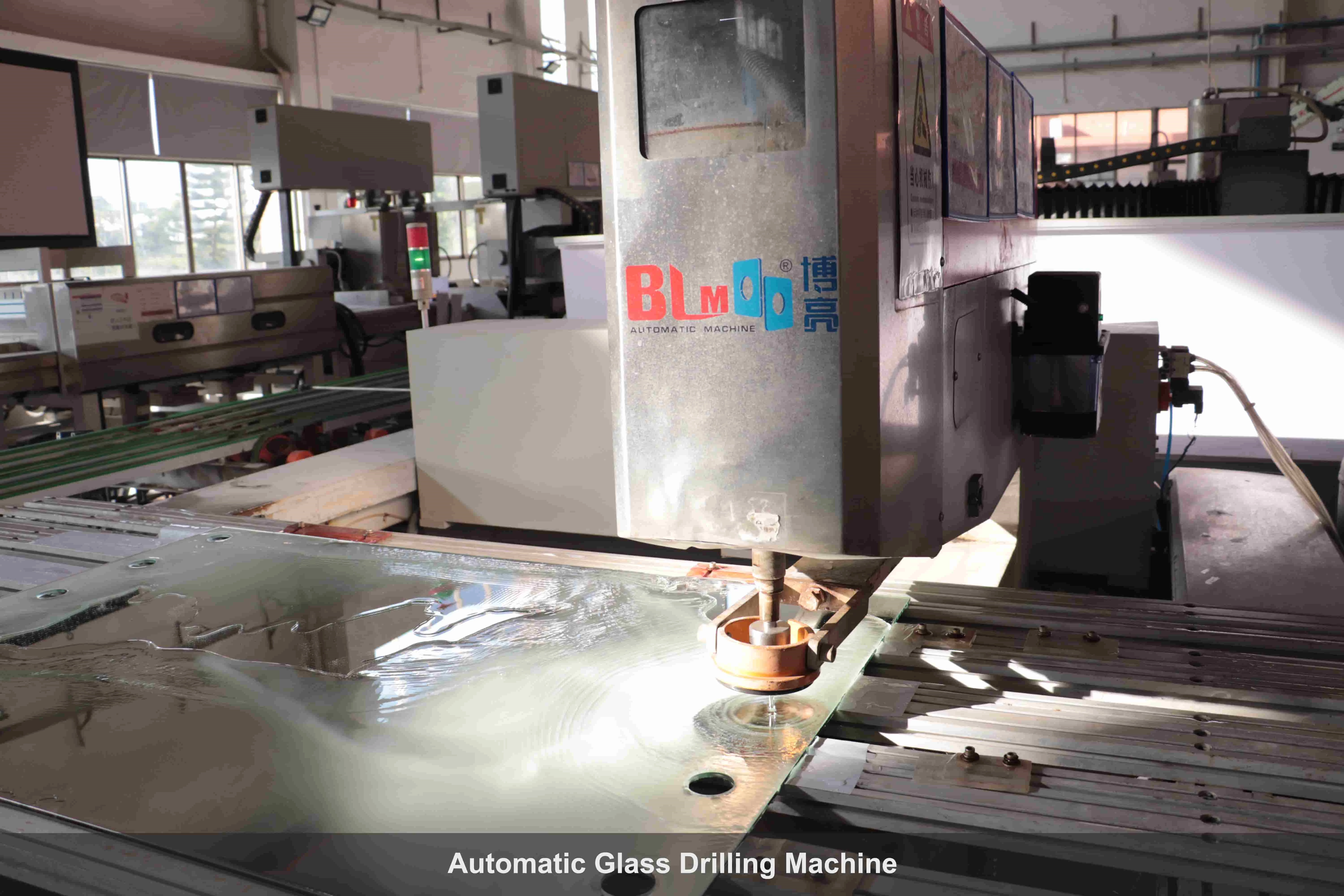

Automatic Drilling Machine

Our Automatic Glass Drilling Machine delivers consistent, high-precision drilling for mirror and glass components. Using automated positioning and stable drilling pressure, the system creates clean, accurately placed holes without chipping or cracks. This ensures perfect compatibility with brackets, LED modules, sensors, and mounting accessories used in modern mirror designs.

Automatic Glass Loading Machine

Our automatic glass loading system streamlines the initial stage of the production line by safely transferring raw glass sheets onto the conveyor with minimal manual handling. Using high-precision suction and positioning technology, the system ensures each sheet is loaded accurately and consistently, reducing breakage risks and improving overall workflow efficiency. This automation also enables stable, continuous production—especially important for large-volume mirror manufacturing.

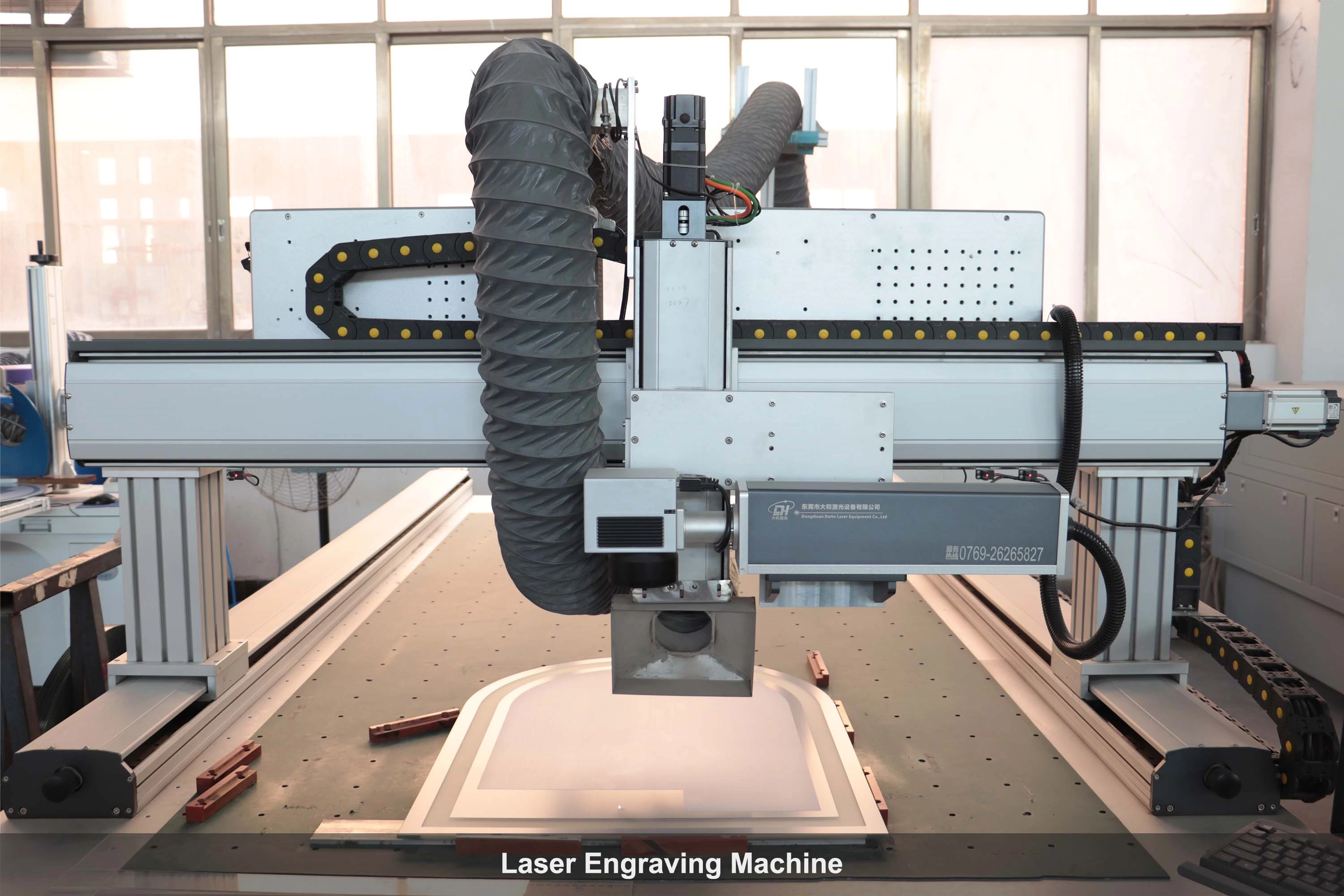

Laser Engraving Machine

Our laser engraving machine delivers ultra-fine detailing on mirror and glass surfaces, enabling precise patterns, scale markings, icons, and branding elements. With stable laser output and controlled engraving depth, the system achieves sharp, clean results without damaging the glass structure—ideal for premium LED mirrors and customized decorative designs.

Aluminum Profile Cutting Machine

Our aluminum profile cutting area ensures highly accurate cutting for mirror frames, structural supports, and LED housing components. Using automated cutting equipment, each aluminum piece is processed with clean edges, consistent lengths, and stable tolerances—ensuring perfect assembly fit for bathroom mirrors, vanity mirrors, and customized mirror structures.

Washing And Drying Machine

Our Automatic Glass Washing & Drying Machine ensures every glass panel enters downstream processes with a spotless, dust-free, and streak-free surface. Using multi-stage high-pressure washing, soft-brush scrubbing, and controlled-temperature drying, the system removes cutting oil, particles, and contaminants—ensuring optimal clarity for mirrors, LED modules, and lamination.

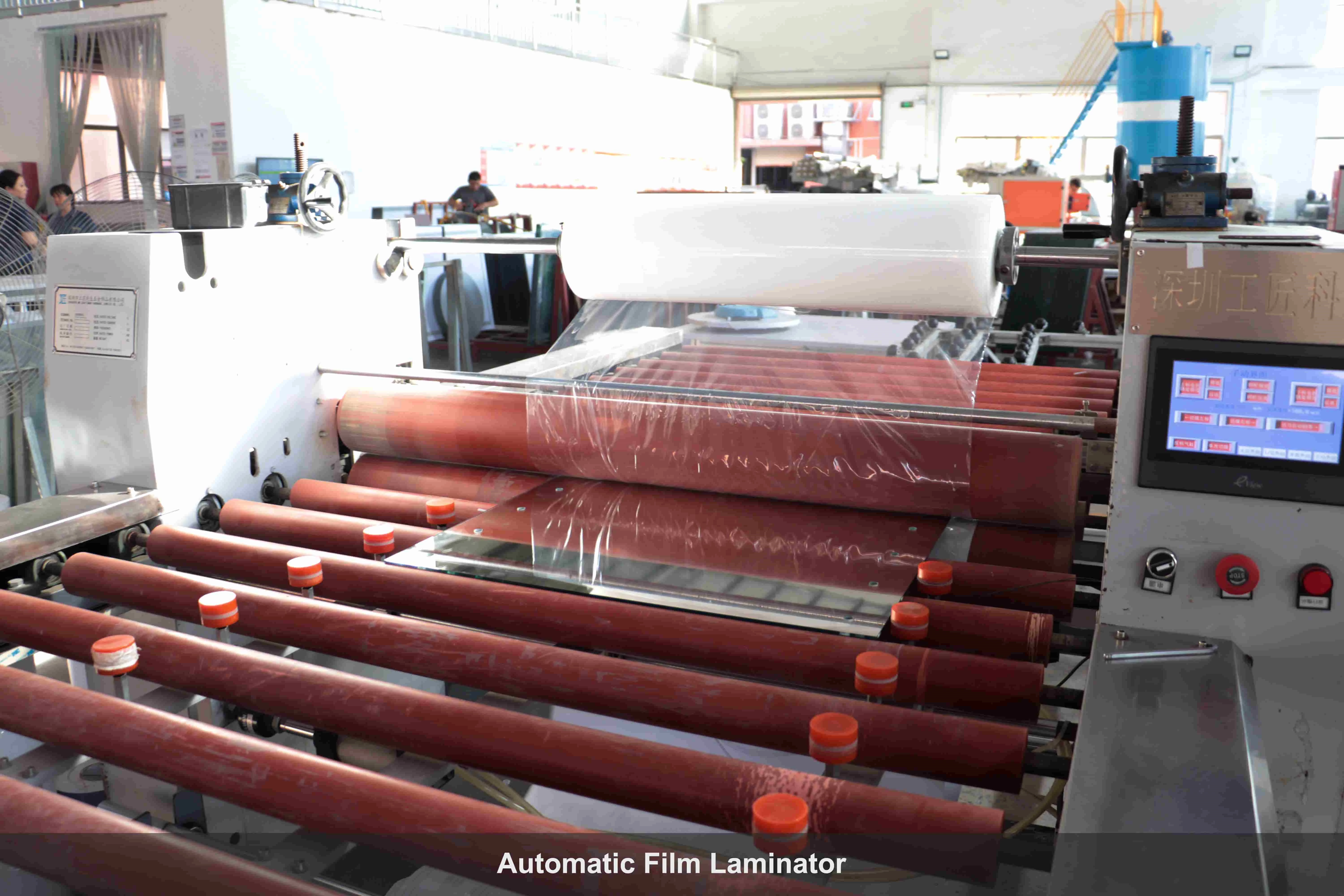

Laminating Machine

Our Automatic Film Laminator applies protective safety films to glass surfaces with consistent pressure and precise alignment. This automated process ensures strong adhesion, smooth coverage, and bubble-free results—greatly improving the safety and durability of finished mirrors. It is an essential step for producing anti-shatter bathroom mirrors and premium-grade LED mirror products.

Anti-Shatter Film Lamination

Our anti-shatter film lamination process ensures that each mirror is reinforced with a strong protective layer, preventing glass fragments from scattering in the event of breakage. This added safety feature is essential for bathroom mirrors, hotel projects, and commercial installations, where durability and user protection are top priorities.