JYD Mirror R&D Center Laboratory

In order to ensure that the company's products can meet the ever-increasing market standards and consumer needs, the company decided to build a professional testing laboratory at the leading level in the industry in 2024, introduce advanced testing equipment, and form a professional testing team. It can conduct comprehensive and accurate testing of product indicators in multiple industries: the test coverage is complete, including environmental testing, aging testing, IP waterproof testing, safety testing, ROSH testing, electronic hardware testing and optical testing and other specialized tests. The experimental test data provides strong support for product research and development and improvement, which significantly improves the development quality of new products and greatly shortens the R&D cycle.

Contact UsJYD Mirror Laboratory Testing Capabilities Overview

To guarantee consistent product quality and meet evolving international standards, JYD Mirror has established a state-of-the-art professional laboratory in 2024. This lab is equipped with advanced instruments and a skilled testing team, dedicated to rigorous environmental and electrical testing. The lab covers low-temperature testing, high-temperature testing, constant humidity testing, electrostatic discharge resistance, and salt spray tests for corrosion resistance.This facility reinforces JYD Mirror’s commitment to quality, safety, and customer confidence.

Constant Temperature and Humidity Test Chamber

At JYD Mirror, it is used to simulate high-temperature and low-temperature environments to evaluate the performance and durability of electronic and mirror products, especially ABS material products. The chamber rigorously tests how materials react under extreme conditions, assessing risks like deformation, drying, explosion, and deterioration. This ensures that every JYD Mirror product maintains reliability and quality even under challenging environmental conditions.

Integrating Sphere – LED Optical Performance Testing

The Integrating Sphere is a vital tool for studying the optical properties and behavior of light waves emitted by LEDs. It is used to measure key performance parameters such as luminous flux (lumens), color temperature (CCT), wavelength, and luminous efficacy. This ensures that every LED used in JYD Mirror products meets strict quality and consistency standards. The system supports full-spectrum testing and delivers precise optical data to verify compliance with product specifications.

Salt Spray Test Chamber – Corrosion Resistance Verification

The Salt Spray Test Chamber is a critical device used to evaluate the corrosion resistance of core materials and protective coatings. It simulates harsh salt mist conditions to test the durability of surface treatments such as electroplating, paint, and anti-rust coatings. This equipment is essential for comparing different protective processes and validating product reliability, especially for metal accessories, electronic components, and coated materials.

Programmable Rain Test Chamber

At JYD Mirror, ensuring the durability and waterproof performance of our products is critical. Our Programmable Rain Test Chamber is specially designed to simulate a wide range of rain and splash environments, verifying the waterproof capabilities of bathroom mirrors, LED mirrors, makeup mirrors, and other electronic products. This equipment accurately replicates real-world weather conditions, allowing us to rigorously test product sealing, water resistance, and durability under various intensities and angles of water exposure.

Drop Test Machine – Impact Resistance for Packaging Integrity

At JYD Mirror, we understand that premium mirrors deserve premium protection—especially during transportation.This machine is used to evaluate the durability of product packaging and analyze potential damage caused by accidental drops during handling, shipping, or logistics. By mimicking drops from multiple angles and heights, we can assess packaging performance, improve structural design, and reduce breakage risks.

Hinge Life Cycle Tester – Durability Testing for Folding Mirror Hinges

To ensure the long-term durability and smooth operation of our foldable and portable makeup mirrors, JYD Mirror employs a specialized Hinge Life Cycle Tester. This equipment is designed to simulate repeated opening and closing of mirror hinges under controlled conditions, accurately replicating real-world usage.By conducting tens of thousands of cycles, the tester helps us evaluate hinge wear, identify mechanical weaknesses, and guarantee consistent performance over time.

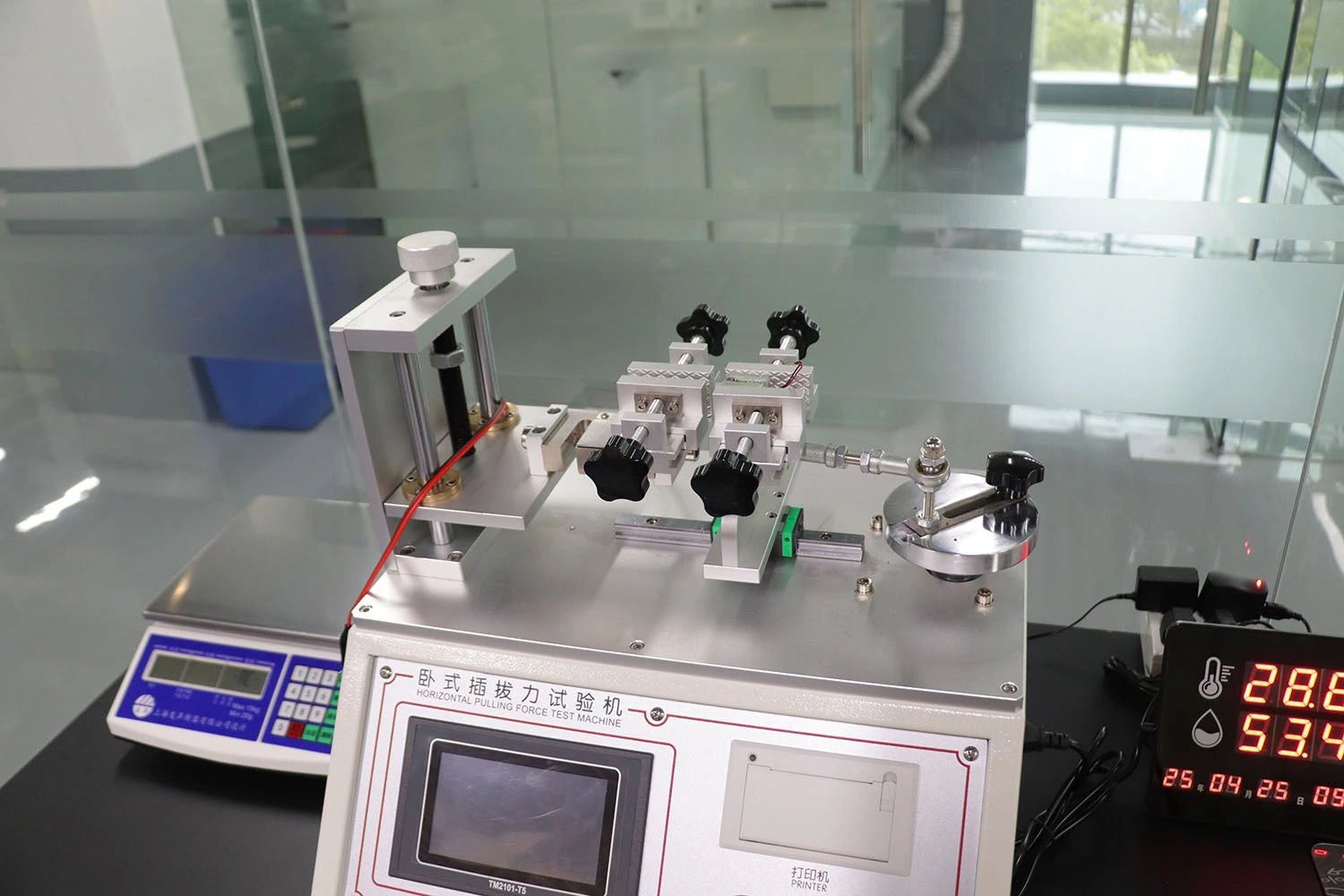

Horizontal Insertion & Withdrawal Force Tester

This specialized testing machine is designed to evaluate the insertion and withdrawal force of connectors, ensuring the durability and reliability of components such as power ports, USB interfaces, and LED light strip connectors in mirrors. It simulates real-world usage to assess the strength and endurance of plug connections, helping improve product structure and assembly quality.

Key Life Cycle Tester – Button Durability Testing

This tester is specifically designed to evaluate the durability of touch and physical buttons used in vanity mirrors, bathroom mirrors, and other smart mirror applications. It simulates repeated pressing operations to assess structural integrity, response sensitivity, and failure thresholds of buttons. Applicable to mechanical switches, touch panels, and sensor zones, the machine offers programmable cycles, force levels, and speed for highly accurate and repeatable testing.

Flip Cover Durability Tester

The Flip Cover Durability Tester at JYD Mirror is used to evaluate the reliability and strength of flip mechanisms on mirror covers and hinged components. By simulating continuous opening and closing cycles, the machine ensures that foldable and rotating mirror designs—such as compact mirrors and folding vanity mirrors—meet high endurance standards. This helps us guarantee product longevity, especially for portable and travel mirrors where hinge performance is crucial.

Flame Retardant Safety Testing Suite

At JYD Mirror, the flame retardant safety testing suite comprises four critical instruments: Needle Flame Tester, Glow Wire Tester, Tracking Index Tester, and Horizontal Burning Tester. These devices are used to comprehensively evaluate the flame retardancy of electronic components, electrical parts, mechanical structures, and injection-molded plastic elements in our LED mirrors. The suite simulates internal faults such as small flame ignition or heat generation due to hardware short circuits, ensuring that each mirror meets stringent global fire safety standards like IEC 60695, UL 94, and GB/T regulations. By implementing this testing process, we guarantee that our bathroom mirrors, vanity mirrors, and smart LED mirrors deliver both functionality and uncompromised fire safety for end-users.

LED Mirror Aging Test

Our Makeup Mirror Assembly Workshop operates multiple high-efficiency assembly lines designed for large-volume, fast-turnaround production. Each line follows standardized SOPs, ergonomic workstation layouts, and streamlined flow management to ensure consistent quality and stable output. Skilled operators handle component fitting, wiring, functional calibration, and cosmetic inspection with precision, while in-line checkpoints guarantee uniformity across every batch. This setup enables us to support diverse product categories—from compact LED mirrors to premium tabletop vanity mirrors—with reliable lead times and excellent production stability.

End-to-End Quality Control Ensuring Every Mirror Meets Professional Standards

Our QC workflow follows a structured, multi-step verification system designed for high-volume OEM/ODM production. Materials undergo incoming quality control (IQC) before entering the line. During assembly, our inspectors check LED boards, wiring, components, brackets, and mirror surfaces to ensure precision and consistency. Before shipping, each mirror goes through functional testing, illumination calibration, touch-switch sensitivity checks, and appearance inspection. This ensures every shipment maintains stable performance and uniform quality across large orders.