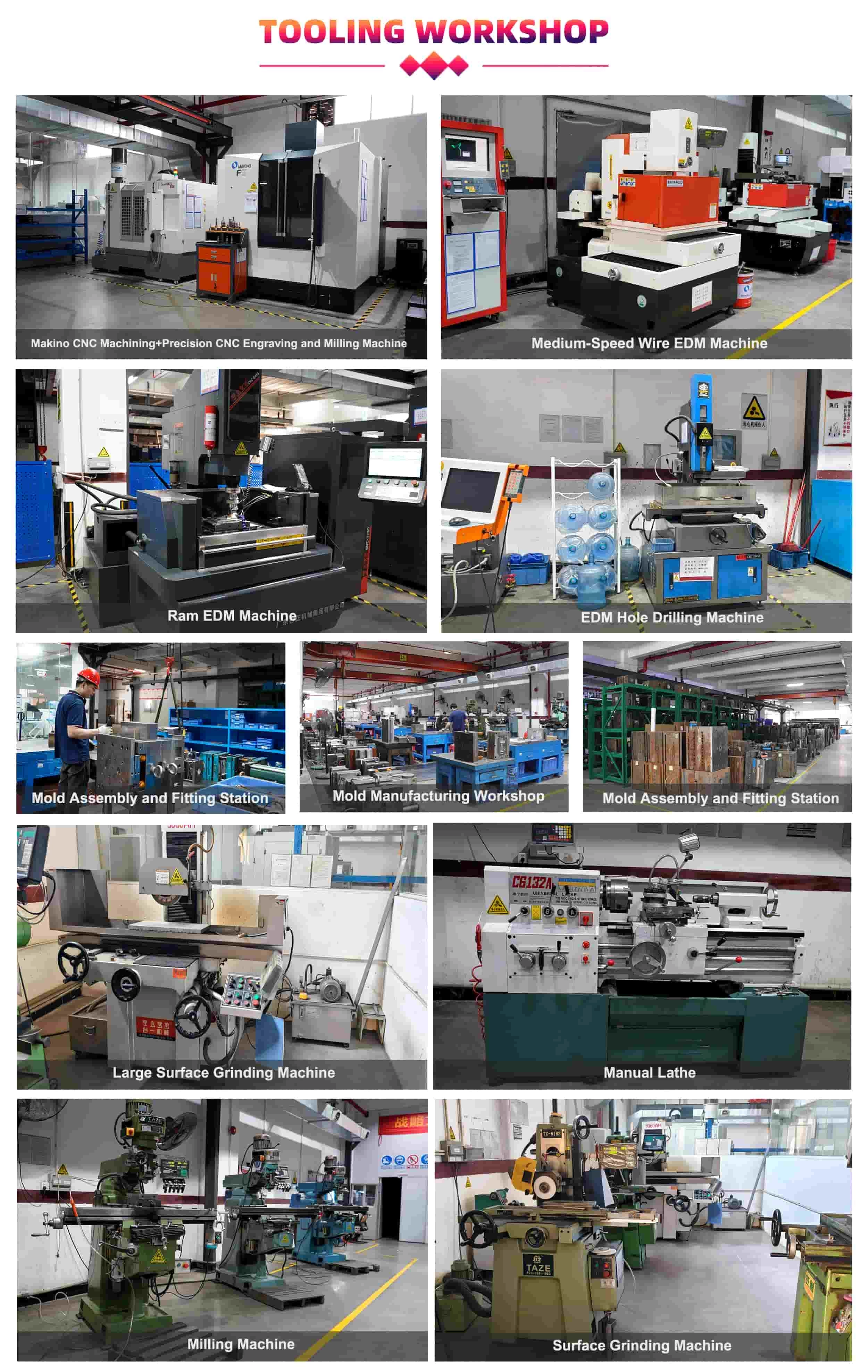

Precision Mold & Tooling Center

Our Precision Mold & Tooling Center integrates advanced machining technology with a fully structured mold-making workflow to support the large-scale production of mirror frames, back plates, structural components, and customized parts used across our LED vanity mirrors, Hollywood mirrors, bathroom mirrors, and mirror cabinets. The center is equipped with Makino CNC machining centers, Jingdiao high-speed engraving & milling machines, medium-speed Wire EDM, Sinker EDM, EDM hole-drilling stations, and complete surface grinding and manual/automatic machining systems, enabling us to achieve ±0.01 mm precision and highly consistent surface finishes.

From DFM evaluation → CAM programming → CNC/EDM machining → fitting & polishing → T1 tryout, every mold follows a rigorous, traceable process designed to shorten development cycles while ensuring maximum mold life and stability in mass production. Dedicated mold assembly and fitting bays allow technicians to fine-tune alignment, optimize cooling channels, adjust parting-line performance, and verify injection parameters before molds enter production.

To guarantee long-term stability, the workshop implements preventive maintenance, on-site refurbishing, and continuous performance monitoring, extending mold lifespan and ensuring reliable operation even under 24/7 high-volume production. Supported by a full range of precision metrology and machining equipment, the Tooling Center delivers fast prototyping, stable mass-production quality, and premium fit-and-finish across all mirror-related plastic components—forming a core foundation for our OEM/ODM capabilities.

Contact Us

Advanced CNC Machining for High-Precision Components

Our Makino CNC machining center and high-speed engraving & milling platform form the core of our precision tooling capabilities. With exceptional rigidity, thermal stability, and micron-level positioning accuracy, these machines ensure superior surface finish, stable dimensional tolerance, and efficient multi-axis operations—supporting mold bases, complex electrodes, aluminum structures, and detailed mirror frame components.

Precision Wire EDM for Critical Mold Features

Our medium-speed Wire EDM machines deliver stable and accurate cutting for complex mold geometries, insert slots, sharp corners, and high-tolerance internal structures. With controlled spark energy and fine wire path management, we ensure consistent wall finish, minimal deformation, and tight dimensional accuracy for mirror-frame molds and structural components.

Advanced Ram EDM for Complex Cavity Precision

Our Ram EDM capabilities enable the machining of intricate mold cavities with exceptional stability and micron-level accuracy. The system delivers consistent spark energy control, allowing us to achieve sharp internal corners, deep ribs, and detailed textures that conventional CNC machining cannot reach. This ensures high-precision molds for mirror frames, back plates, brackets, and decorative components.

High-Speed Small-Hole EDM Drilling for Mold Cooling Optimization

The EDM Hole Drilling Machine enables rapid creation of micro holes—even on hardened steel—making it ideal for cooling-channel inlets, ejector pin holes, and start holes for wire-cut EDM. This significantly enhances mold thermal performance and ensures stable cycle times in mass injection molding.

Precision Turning for Mold Components

Our manual lathe station enables precise turning, facing, threading, and shaft processing for a wide variety of mold components and auxiliary parts. Skilled machinists perform fine adjustments that automated systems cannot easily achieve, ensuring excellent concentricity, dimensional stability, and fitment accuracy for mold assemblies.

Ultra-Flat Surface Grinding for Mold Bases

Our large surface grinding machine ensures exceptional flatness and parallelism for mold bases, plates, and precision blocks. With controlled feed and stable rigidity, we achieve superior surface quality, which is critical for mold alignment, sealing performance, and long-term operational reliability.

Versatile Milling for Complex Geometry & Structural Parts

Our milling machines support slotting, contour shaping, drilling, beveling, and face milling for mold components and structural hardware. This versatility allows efficient processing of prototypes, customized parts, and critical features that require strong dimensional control.

Fine Surface Grinding for High-Precision Mold Inserts

Our precision surface grinding machine produces ultra-smooth, dimensionally accurate surfaces for mold inserts, sliders, and wear plates. This finishing process ensures excellent mold fitment, reduced friction, and extended mold life under high-cycle operation.

Precision Mold Assembly & Fitting Operations

Our mold assembly and fitting station is equipped to handle complex structures with tight tolerances. Skilled technicians perform alignment, polishing, parting-line optimization, and functional verification to ensure every mold meets production-ready standards. Each unit undergoes controlled assembly sequences and pre-run evaluation to guarantee smooth mold opening/closing, stable cooling circuits, and long-term durability under high-cycle production.

Integrated Mold Manufacturing for Complex Tooling

Our mold manufacturing workshop consolidates CNC machining, EDM processing, surface grinding, drilling, and bench work into a streamlined workflow. With organized workstations and overhead crane systems, the workshop supports simultaneous production of multiple molds. This integrated environment enables fast lead times, stable quality, and reliable delivery for injection molds used in LED mirrors, cosmetic mirrors, bathroom mirrors, and structural components.

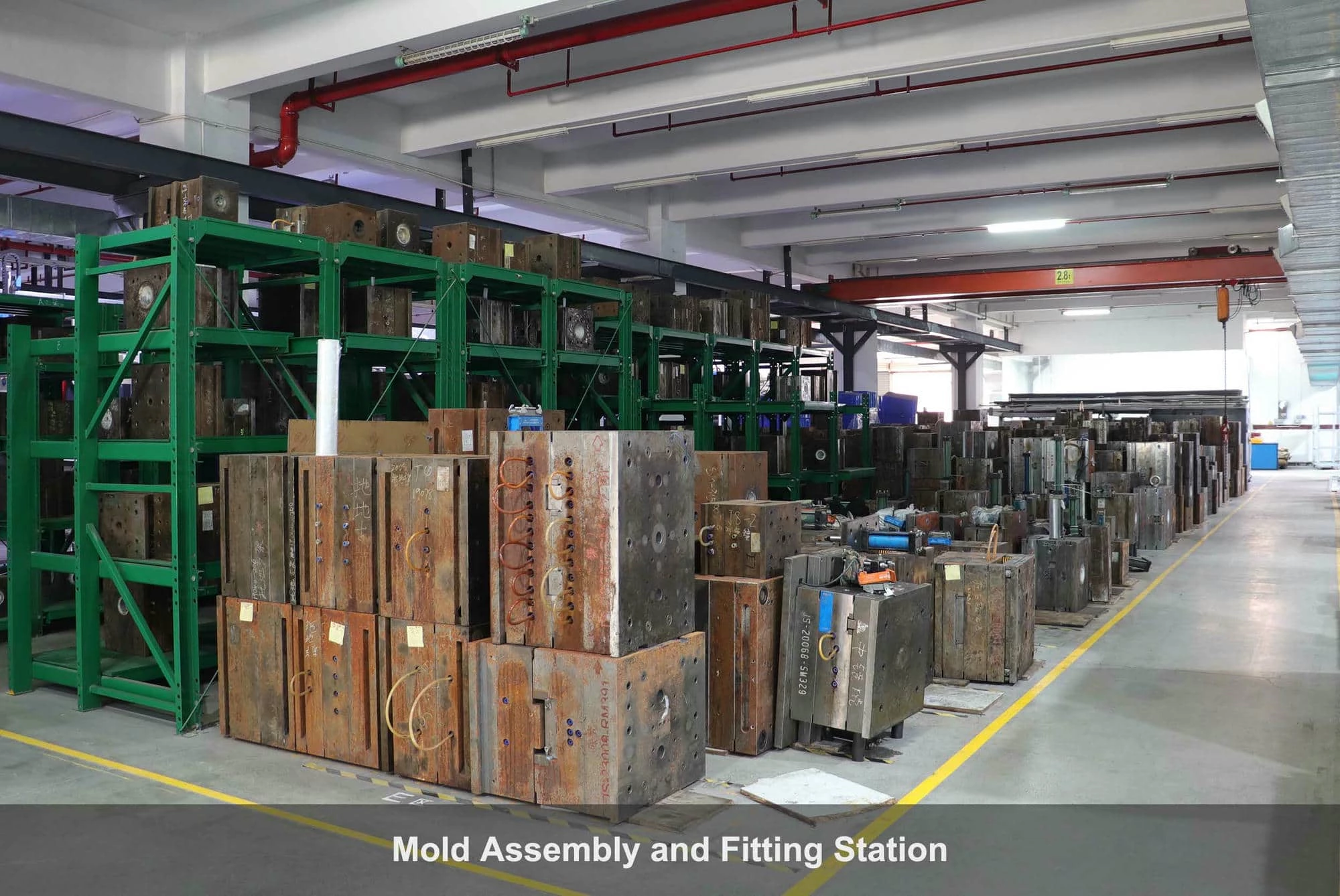

Organized Mold Storage for Efficient Production Management

The mold warehouse houses a large inventory of production molds, stored on heavy-duty racking systems for safety and easy retrieval. Each mold is categorized and tagged for traceability, enabling fast switching between SKUs and improving production flexibility. Strict environmental controls and maintenance routines ensure molds remain in optimal condition even during long storage periods.